Hydroformed Chassis: Redefining Vehicle Structure

Revolutionizing automotive design, hydroforming technology has quietly transformed the way we build vehicle chassis. This innovative process, which uses high-pressure fluid to shape metal, is reshaping the automotive landscape. From increased structural integrity to weight reduction and design flexibility, hydroforming is pushing the boundaries of what's possible in vehicle manufacturing. But what exactly is hydroforming, and how is it changing the game for automakers and drivers alike?

The automotive industry first adopted hydroforming for exhaust systems and engine cradles. As the technology matured, it expanded to more critical structural components, including frame rails, roof pillars, and entire chassis structures. This shift marked a significant departure from traditional welded multi-piece frames, offering automakers new possibilities in vehicle design and performance.

The Mechanics Behind Hydroforming

At its core, hydroforming is a relatively straightforward process. A tubular metal blank is placed into a die cavity that matches the desired final shape. The ends of the tube are sealed, and high-pressure fluid (typically water mixed with lubricants) is pumped into the tube. As the pressure increases, often reaching up to 100,000 psi, the metal expands to fill the die cavity.

The process allows for precise control over the metal’s deformation, resulting in components with tight tolerances and excellent surface finish. Moreover, hydroforming can create complex shapes with varying cross-sections and wall thicknesses, something that’s challenging to achieve with traditional stamping methods.

Structural Integrity: The Hydroforming Advantage

One of the primary benefits of hydroforming in chassis construction is the significant improvement in structural integrity. Hydroformed parts are typically stronger and more rigid than their welded counterparts. This is due to the elimination of weld seams, which are often weak points in traditional chassis designs.

The continuous, seamless nature of hydroformed components distributes stress more evenly across the structure. This results in improved crash performance, as the chassis can better absorb and dissipate impact energy. Additionally, the ability to vary wall thickness within a single component allows engineers to reinforce high-stress areas without adding unnecessary weight to the entire structure.

Weight Reduction: Driving Efficiency

In the constant pursuit of improved fuel efficiency and performance, weight reduction is a key focus for automakers. Hydroforming plays a crucial role in this effort. By creating complex, single-piece components, hydroforming eliminates the need for multiple stamped parts and their associated welding or fastening.

This reduction in parts count not only simplifies assembly but also significantly reduces overall vehicle weight. A hydroformed chassis can be up to 30% lighter than a traditional welded frame while maintaining or even improving structural integrity. This weight savings translates directly into improved fuel efficiency, handling, and performance.

Design Flexibility: Pushing the Boundaries

Perhaps one of the most exciting aspects of hydroforming is the design freedom it offers automotive engineers. The ability to create complex, three-dimensional shapes with varying cross-sections opens up new possibilities in vehicle packaging and styling.

Hydroformed components can be designed with tighter radii and more intricate geometries than stamped parts. This allows for more efficient use of space within the vehicle, potentially leading to larger interiors without increasing the overall vehicle size. Furthermore, the smooth, seamless nature of hydroformed parts can contribute to improved aerodynamics, further enhancing vehicle efficiency and performance.

Challenges and Considerations in Hydroforming

While hydroforming offers numerous advantages, it’s not without its challenges. The initial tooling costs for hydroforming can be higher than those for traditional stamping processes. This can make hydroforming less economical for low-volume production runs.

Additionally, the process requires specialized equipment and expertise, which may necessitate significant investment for manufacturers transitioning to this technology. The high pressures involved in hydroforming also demand careful material selection and process control to prevent defects such as wrinkling or bursting.

The Future of Hydroformed Chassis

As automotive manufacturers continue to push for lighter, stronger, and more efficient vehicles, hydroforming is likely to play an increasingly important role. The technology is continuously evolving, with advancements in computer simulation and process control improving part quality and reducing development time.

We’re also seeing the integration of hydroforming with other advanced manufacturing techniques, such as 3D printing for rapid prototyping and die creation. This synergy is accelerating the development cycle for new vehicle designs and enabling even more complex and efficient chassis structures.

Impact on Vehicle Performance and Safety

The adoption of hydroformed chassis components has had a profound impact on vehicle performance and safety. The increased structural rigidity provided by hydroformed parts translates into improved handling and ride quality. Vehicles with hydroformed chassis often exhibit less flex and body roll during cornering, resulting in a more responsive and controlled driving experience.

From a safety perspective, the uniform stress distribution and improved energy absorption characteristics of hydroformed structures contribute to enhanced crash protection. In frontal and side impacts, hydroformed frame rails and pillars can more effectively crumple and redirect force away from the passenger compartment.

Hydroforming Beyond the Chassis

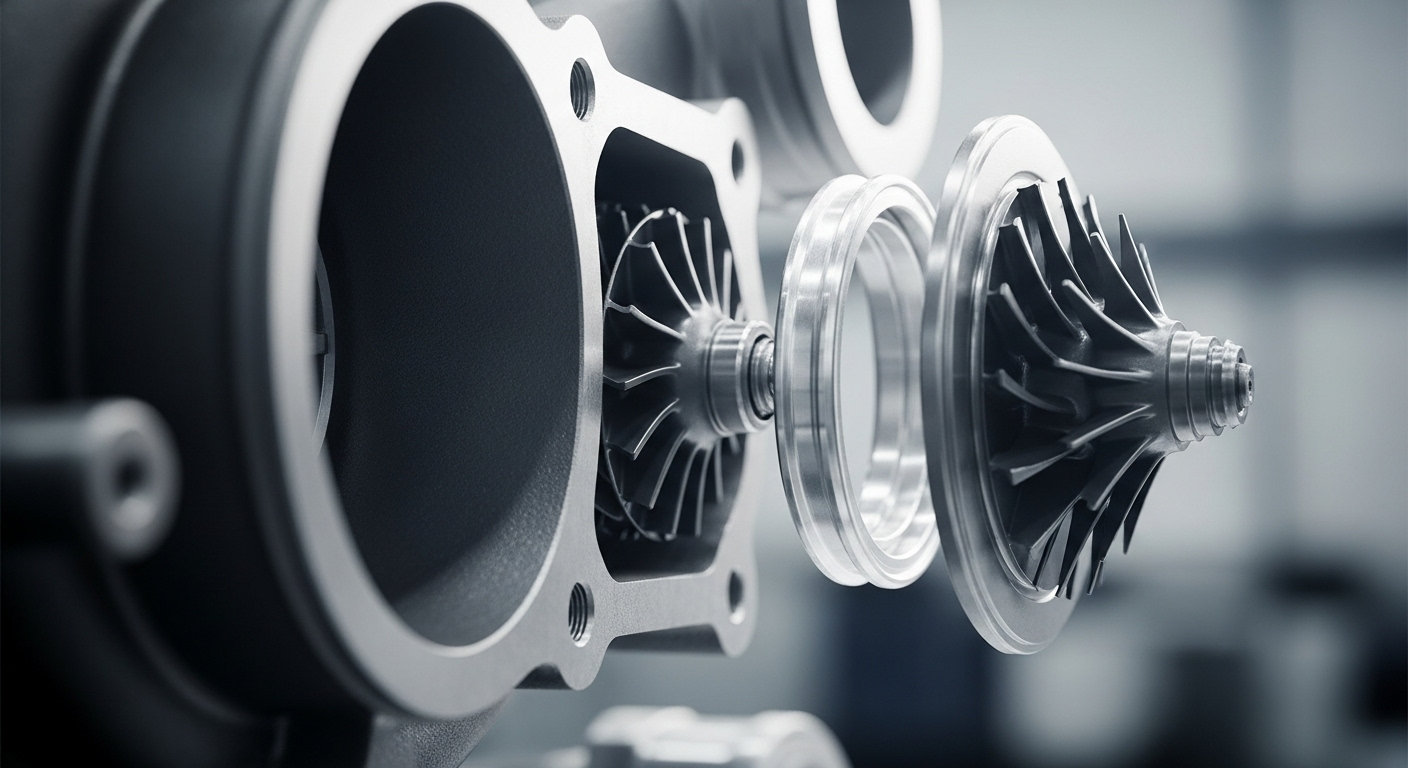

While chassis components remain the primary application of hydroforming in the automotive industry, the technology is finding its way into other vehicle systems. Hydroformed parts are increasingly being used in powertrain components, such as intake manifolds and exhaust systems. These applications benefit from the same advantages of weight reduction and design flexibility seen in chassis components.

The process is also being explored for the creation of complex body panels, potentially revolutionizing vehicle aesthetics. As hydroforming technology continues to advance, we can expect to see its influence expand throughout the vehicle, from the frame to the exterior and beyond.

In conclusion, hydroforming technology represents a significant leap forward in automotive chassis design and manufacturing. By enabling the creation of lighter, stronger, and more complex structural components, it’s helping automakers meet the ever-increasing demands for efficiency, performance, and safety. As the technology continues to evolve, we can expect to see even more innovative applications that push the boundaries of what’s possible in vehicle design and engineering.